Ever wonder what keeps Sydney’s harbours, bridges, and warehouses looking sharp under the punishing Aussie sun? Industrial painting is the unsung hero behind the scenes, turning dull, rust-prone steel into sleek, protected assets.

For instance, specialized coatings act like SPF50 sunscreen for metal – blocking UV rays, salt spray and chemical splashes. Those high-tech paints are literally a suit of armour for your facility, shielding it from corrosion and decay. It’s not just vanity; it’s practical protection.

In short, this is a long-term investment. Those coatings significantly extend the life of your assets, saving you time, money and headaches on repairs down the line.

What Is Industrial Painting?

You might wonder, how is it different from your typical house or office paint job? Picture painting the Sydney Harbour Bridge versus a suburban bedroom—two very different beasts. Industrial painting focuses on protection and durability, not just looks.

It requires special knowledge of corrosive environments and heavy materials. In industrial settings, the focus is on shielding surfaces from rust, moisture and wear. The goal is simple: extend asset life and keep everyone safe.

For example, it’s all about long-term asset protection think of Industrial painting like giving metal structures a suit of armour. It’s not just a fresh coat of colour; those specialized primers and epoxies literally keep moisture, salt and chemicals off your steel.

One industry guide even puts it bluntly: industrial coatings “aren’t just about aesthetics—it’s about protecting assets, ensuring safety, and boosting operational efficiency”. In other words, it’s engineering in disguise, using paint as protection.

Industrial Painting Services in Sydney

So what exactly do painters do on an industrial site in Sydney? A lot more than you might think. These crews handle everything from oil tanks to gantry cranes. Common services include:

- Surface Preparation: Deep cleaning and blasting the steel (sandblasting or high-pressure wash) to remove rust, old paint and oil. This “prep” step ensures the new coating sticks properly.

- Anti-Corrosion Coatings: Applying epoxy primers or zinc-rich paints that block rust. Sydney’s salty harbour breeze can eat away steel, so these primers act like rust-proof raincoats.

- High-Performance Paints: Using industrial-grade epoxies and polyurethanes for floors, machinery and structures. These paints stand up to impact, chemicals and UV better than ordinary wall paint.

- Fire-Retardant Paint: In many factories you’ll see intumescent coatings on steel. These special paints expand under heat and slow fire spread, a must-have for safety compliance.

- Anti-Slip Floor Coatings: Rough epoxy or acrylic coatings on concrete floors give grip. In a wet Sydney warehouse, no one wants to slip with a forklift!

- Line Marking & Safety Signs: Painting bright walkways, hazard symbols and exit paths. Under NSW WHS rules, clear line-markings and colour-coded areas keep everyone safe.

- Equipment & Tank Painting: From cranes and silos to chemical drums, any large asset can be repainted. Often this includes branding or logos as part of the finish.

- Maintenance Touch-Ups: Even after a big paint job, painters come back for touch-ups. A little patch now prevents a big refurbishment later.

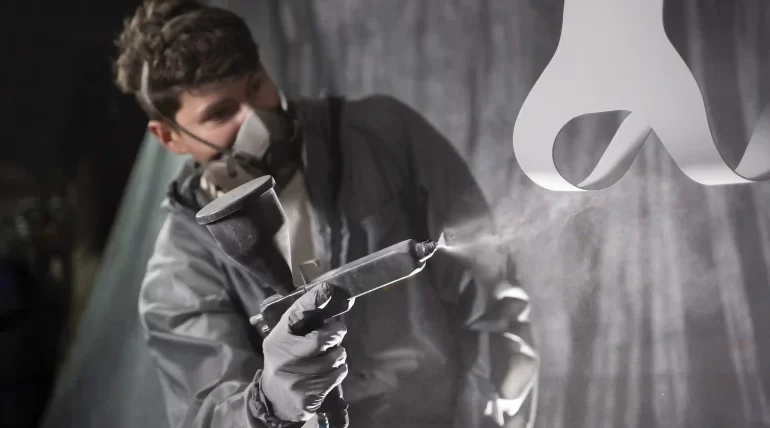

Essentially, a Sydney contractor offers a full suite of services that go way beyond a simple roller and bucket. They bring scaffolding, safety harnesses and high-pressure sprayers, and follow strict PPE and containment rules. Sydney’s industrial painting experts stress that “you need expertise in corrosion control, epoxy systems, fireproofing and abrasive blasting” to do the job right.

The Industrial Painting Process: Step by Step

Let’s break down the painting process into bite-sized pieces. Each step must be done just right:

Assessment & Planning

The team inspects the site with you. They note any rust spots, metal types, and your performance needs (e.g. “needs to be food-safe” or “fire-rated”). Together you choose the coatings and schedule the work.

Surface Preparation

This is arguably the most important step. Painters remove dirt, grease and old coatings with sandblasting, wire-brushing or pressure washing. Proper preparation creates a clean, roughened surface so the new paint bonds strongly. (Skip this and new paint can peel off in months.)

Proper surface preparation is critical for long-term corrosion protection. NSW government specifications for protecting steelwork using paint coatings clearly state that inadequate preparation significantly reduces coating performance and service life, which is why abrasive blasting and thorough cleaning are non-negotiable on industrial sites.

Priming

Once the steel is bare and dry, an anti-corrosion primer is applied. These primers often have rust-inhibitors or epoxy ingredients. They form the first layer of defence and ensure the finish coat sticks well. For example, a zinc-rich epoxy primer locks down the surface before colour goes on.

Main Coating

Now for the color coats. Technicians spray or roll on the chosen industrial paint (epoxy, polyurethane, etc.) in multiple layers. Each coat must hit a specified thickness. Often they use airless sprayers to cover large areas quickly and evenly. You’ll typically see a mid-coat and then a final topcoat for durability. They control temperature and humidity so the paint cures perfectly.

Curing & Inspection

After painting, the surface is left to cure (dry and harden). Crews might use heat lamps or just time for this. Then they do a careful inspection—measuring coating thickness, checking adhesion and looking for any pinholes. If any defect is found, they fix it before leaving. The goal is a flawless, rock-solid finish.

| Step | What Happens |

| Assessment & Planning | Inspect site, discuss coatings & schedule the work. |

| Surface Preparation | Clean and blast surfaces to remove rust and contaminants. |

| Priming | Apply rust-inhibiting primer for adhesion and extra protection. |

| Coating Application | Spray or roll on industrial-grade paint layers (epoxy, polyurethane, etc.). |

| Curing & Inspection | Let paint harden; then inspect thickness, adhesion and finish quality (repair defects if needed). |

Throughout each phase, safety is key. Painters wear full PPE (respirators, coveralls) and keep dust contained. In NSW they follow strict WHS codes on ventilation and waste disposal. The result? A rock-solid paint job that’s as much science as craftsmanship.

Benefits of Industrial Painting

Now for the real question: Why bother? Besides looking crisp, industrial painting delivers hard-dollar advantages and safety perks. Here’s why businesses invest in it:

Extended Asset Life:

These tough coatings are like giving steel a suit of armour. They block rust, moisture and abrasion. Industry stats even show up to 300% ROI over 5 years by reducing maintenance. In short, you delay major repairs (and replacement) by decades.

Safety & Compliance:

A properly painted facility meets WHS standards. Brightly painted walkways, anti-slip floors and fire-retardant surfaces keep your people safe and regulators happy. Nobody trips over a faded line or ignores a rusty rail that should’ve been painted.

Operational Efficiency:

Clean, even floors and bright walls improve workflow. In practice, a professional paint job reduces downtime and boosts productivity. Forklifts move more smoothly, inspections catch leaks sooner, and better lighting (off fresh white paint) keeps operators alert. Your plant runs a bit smoother every day.

Aesthetics & Brand Image:

Let’s be honest, it feels good to work in a sharp-looking space. A clean, freshly-painted plant or crane sends a message of quality. It boosts employee morale and shows customers/investors you care. A branded logo on the wall reminds everyone who they’re working for.

Cost-Efficiency:

Investing a bit more upfront often saves you in the long run. Premium coatings and thorough prep mean fewer touch-ups and lower maintenance costs. It’s like buying quality work boots: they cost more, but they last much longer and prevent injuries (and expense) down the road.

How to Choose an Industrial Painting Contractor

Alright, so this is a big deal – how do you pick the right contractor? Think of it like vetting a mechanic for your car, but the stakes are higher. Here are some tips:

Experience & Accreditation:

Go with a team that lives in the industrial world. Ideally, they’ve done 10+ years of projects and hold certifications (ISO, Dulux/Wattyl accreditation, etc.). A track record with big clients or industry group memberships (like AWCI) is a good sign.

Licenses & Insurance:

In NSW, make sure your painters are properly licensed. They should carry public liability and workers’ compensation insurance. This protects you if someone gets hurt or a large-scale accident happens on site.

Safety Culture:

Watch how they operate. Check that the crew uses scaffolds and lifts safely and follows all WHS protocols (see Safe Work Australia’s guidelines on safe painting). A responsible contractor will pause work for the smallest hazard.

Detailed Quote:

As I learned the hard way, always get a written quote that lists every step (surface prep, paint type, labour, timeline). A good quote leaves nothing to guess. It should explain the number of coats, brands of paint, site access logistics, and warranty details.

Local Knowledge:

A Sydney specialist knows our climate and council rules. They’ll recommend UV-resistant paints for Bondi or anti-corrosives for Manly, and handle any council permits. Ask if they’ve worked in your industry (e.g. food, oil & gas).

Reputation:

Check reviews or ask around. The best painters book months ahead. If everyone raves about a company’s reliability and finish, that’s a strong endorsement.

Choosing the right industrial painter is about trust and track record. After all, you’re handing them a $100,000+ asset. A smart manager will interview multiple painters, just like hiring for any other crucial role.

Conclusion

Okay, painting metal isn’t glamorous – nobody’s spraying stripes on forklifts for fun. Think of it as giving your factory its own sunscreen, rust-proof suit and brand boost all in one. No matter how smooth it looks, getting that final glossy coat takes skill and care.

When you choose a qualified industrial painter (with solid experience and insurance) and use premium coatings, you’ll see the results every day: no corroded beams, bright floors, and zero slip accidents. Plus, a fresh coat tells visitors and workers alike that you run a top-notch operation.

Ready to give your Sydney facility a makeover that lasts? Reach out to a local industrial painting specialist to get a quote. Your future self will thank you when you’re not fixing leaks or fighting rust!

FAQs

How often should industrial coatings be reapplied?

Typically, industrial coatings last about 5–7 years before needing a fresh coat. Harsh conditions (salt air, heavy use) can push that schedule shorter.

What types of coatings do industrial painters use?

Painters often use tough epoxy or polyurethane systems for durability, along with acrylic and fire-retardant paints as needed. These options are chosen to match each facility’s needs.

Will industrial painting disrupt my operations?

Yes, but professionals minimize downtime. Crews frequently paint outside business hours (nights/weekends) and use fast-curing materials, so your facility can keep running.